Unveiling the Construction of Wire Rope: Understanding its Four Essential Components

- Bundit Suriyaburaphakul

- May 30, 2023

- 1 min read

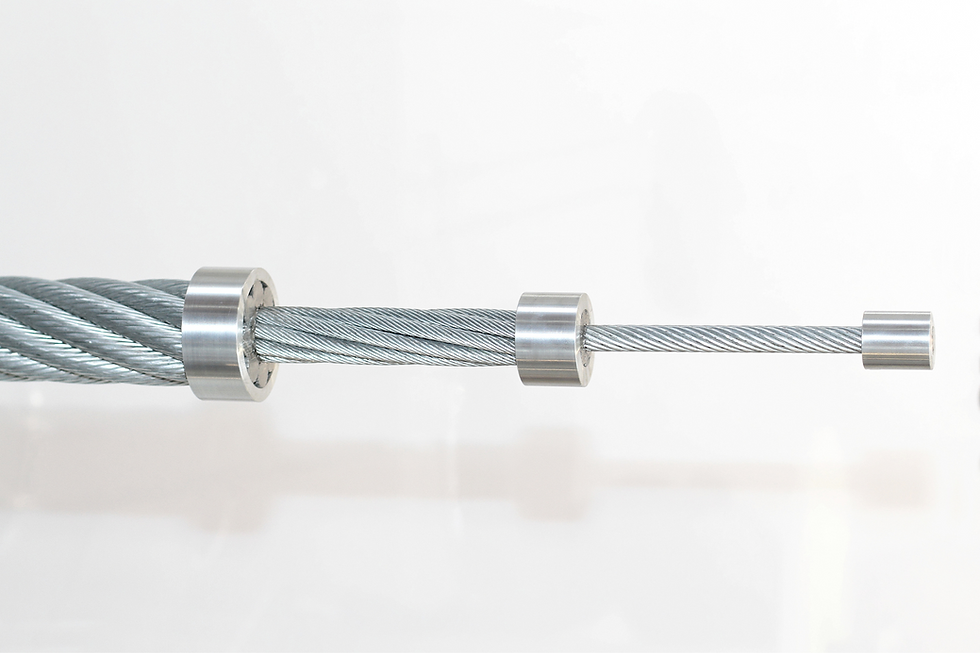

Wire rope, as a fully assembled entity, is composed of four key components that collectively form its design:

Wires: These metal strands join together to create a singular strand. Wires can be fabricated from various materials such as steel, iron, stainless steel, monel, and bronze. Different grades of wires offer specific characteristics, including strength, wear resistance, fatigue resistance, corrosion resistance, and curvature.

Strands: Multiple wires are twisted and arranged to form multi-wire strands. These strands are then helically laid around the core of the rope. Strands with larger diameter wires exhibit higher resistance to abrasion, while those with smaller diameter wires offer greater flexibility.

Core: The core runs through the center of the wire rope, providing support to the strands and maintaining their relative position during loading and bending. Cores can be crafted from various materials, including natural or synthetic fibers, as well as steel.

Lubrication: During the manufacturing process, wire rope is coated with lubrication that permeates through to the core. This lubrication serves two main purposes: reducing friction between wires and strands as they move, and offering corrosion protection and lubrication for the core, inner wires, and outer surface.

Understanding these four essential components provides valuable insight into the construction and functionality of wire rope. Each component plays a vital role in determining the rope's strength, flexibility, resistance to wear and corrosion, and overall performance.

.png)

Commentaires